In recent years, Low-cis Polybutadiene Rubber (LCBR) has emerged as a key player in revolutionizing the landscape of industrial plastic modification and tire applications. This paradigm shift is driven by its versatile properties and environmentally conscious production methods.

High Impact Polystyrene (HIPS) and ABS Applications: LCBR has gained remarkable prominence in modifying plastics, particularly in high impact polystyrene (HIPS) and Acrylonitrile-Butadiene-Styrene (ABS). Its compatibility and performance attributes make it the product of choice for enhancing the structural and impact resistance of these materials.

LCBR plays a pivotal role in tire applications, contributing to enhanced resilience and abrasion resistance. Its inclusion in tire formulations, especially in high-performance tires, leads to improved overall tire performance, emphasizing the critical importance of LCBR in the automotive industry.

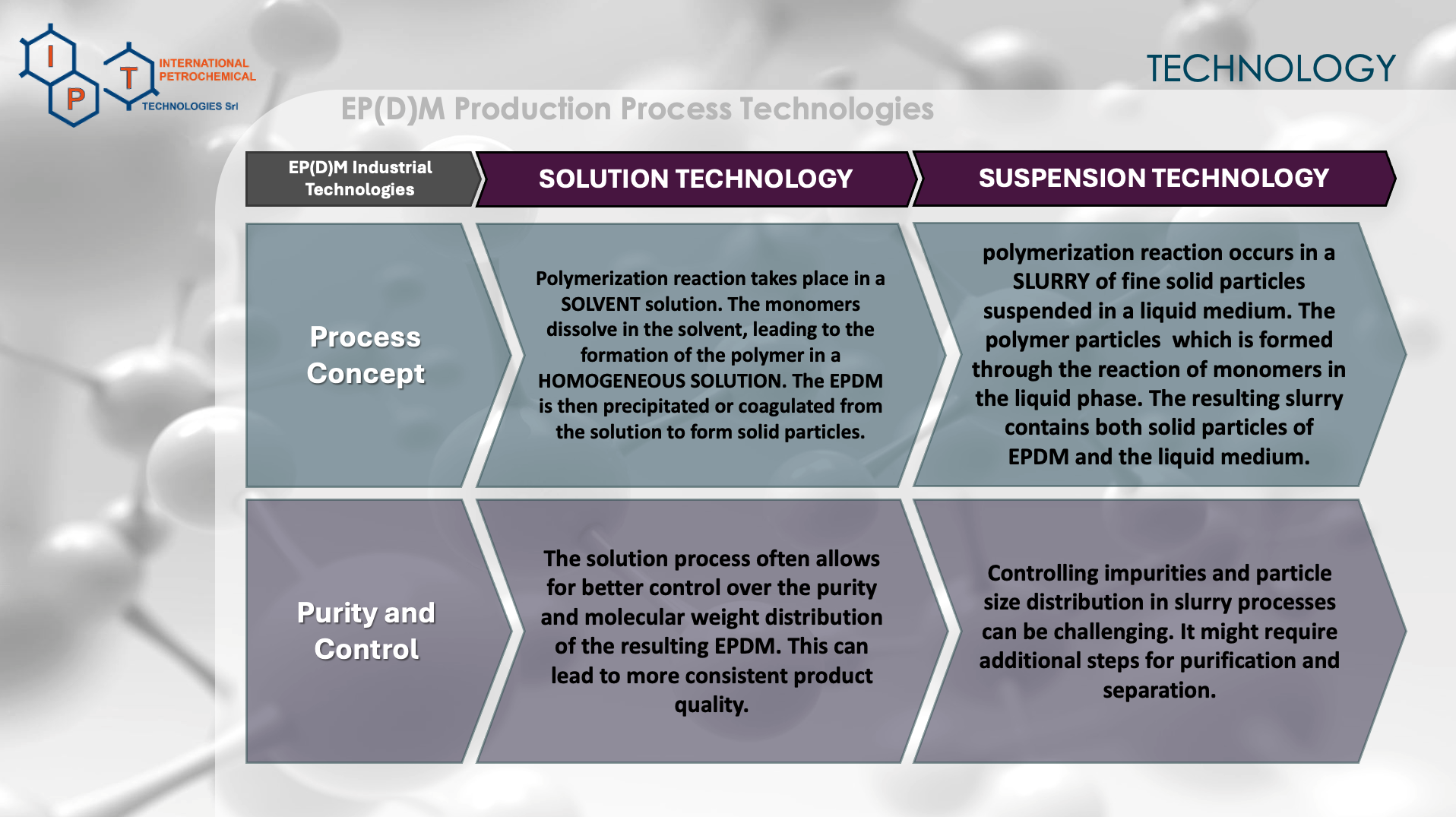

LCBR’s commitment to environmental sustainability is underscored by its production method through solution polymerization in an aliphatic solvent. This innovative approach significantly reduces the environmental impact associated with traditional rubber production methods, making LCBR a more sustainable choice.

Positive Impact on the Environmental Footprint: By adopting solution polymerization in an aliphatic solvent, LCBR not only enhances the efficiency of the production process but also minimizes the use of harmful substances. This results in a positive impact on the overall environmental footprint, aligning with global efforts towards greener industrial practices.

In the plastic modification sector, continuous LCBR finds its application in high viscosity styrene-LCBR solutions, ensuring a consistent and high-quality modification process.

Batch LCBR for Low Viscosity Styrene-LCBR Content: The versatility of LCBR is evident in its application as batch LCBR for low viscosity styrene-LCBR content. This flexibility allows for tailored solutions in plastic modification processes.

Styrene-(Tapered)-Butadiene Batch for ABS: In ABS applications, the Styrene-(tapered)-Butadiene batch showcases LCBR’s adaptability and effectiveness, contributing to the unique characteristics required for Acrylonitrile-Butadiene-Styrene products.

In conclusion, LCBR’s multifaceted role in industrial plastic modification and tire applications reflects a sustainable and forward-thinking approach. Its compatibility with various polymers and environmentally friendly production methods position LCBR as a catalyst for positive change within the industry. As we continue to navigate the evolving landscape of materials science, LCBR stands out as a symbol of innovation, performance, and environmental responsibility.