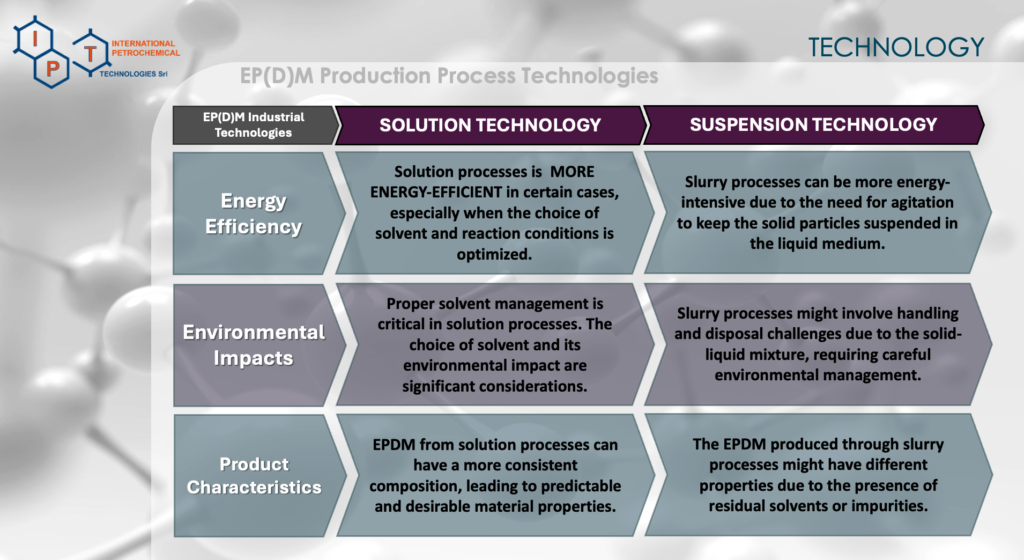

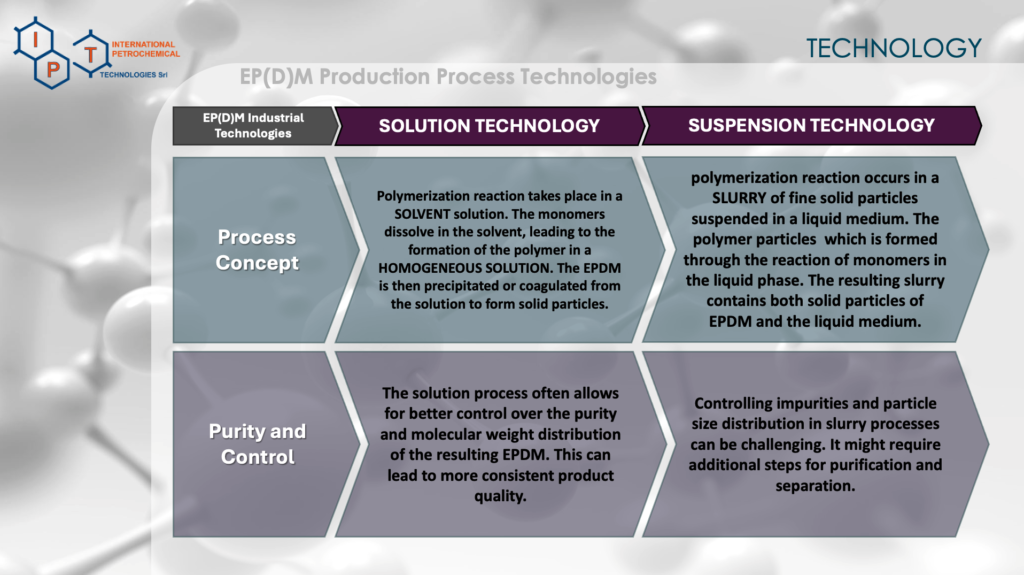

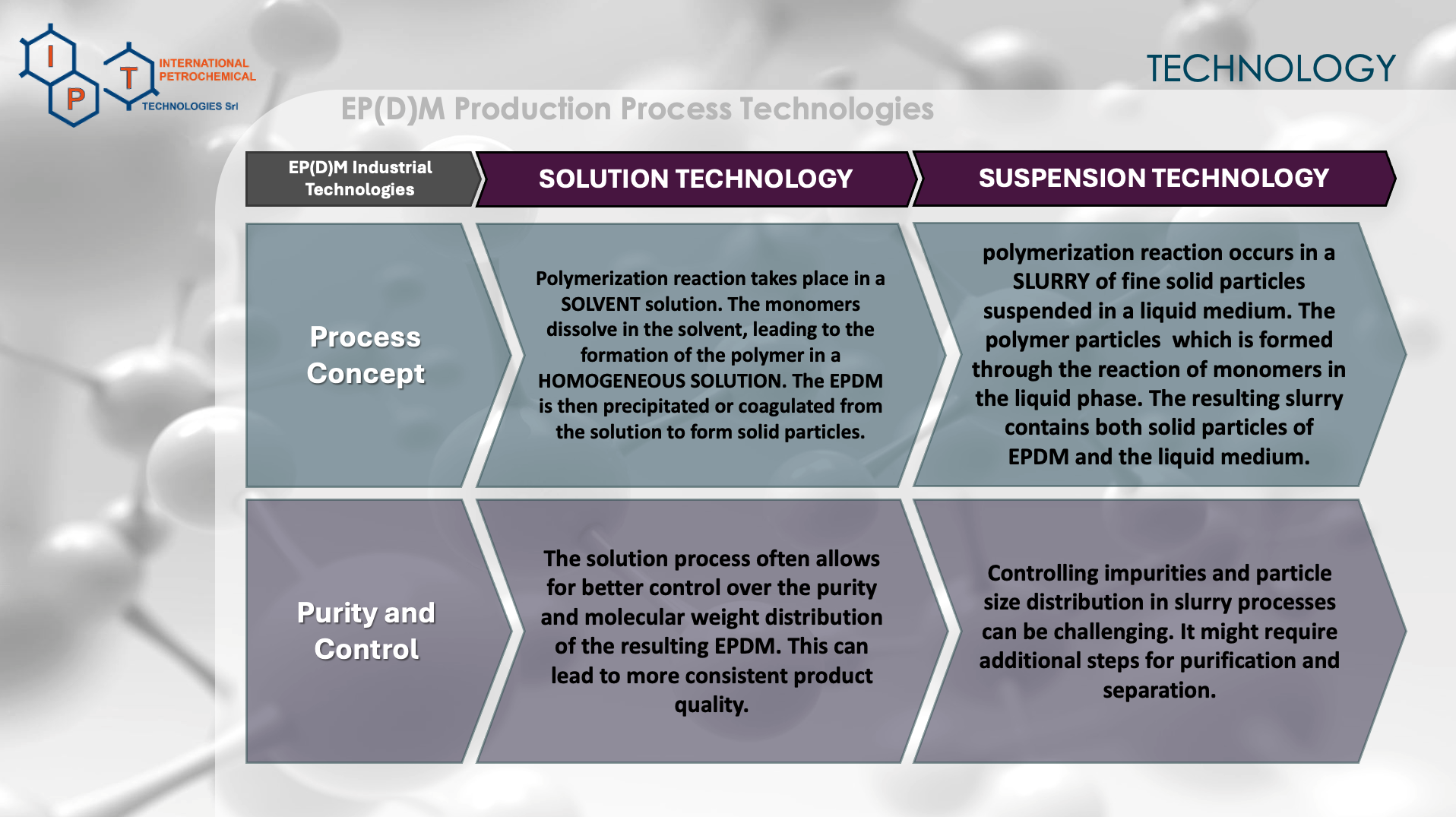

EPDM (Ethylene Propylene Diene Monomer) can be produced through different polymerization methods. Today the available commercial processes are Solution polymerization and Suspension polymerization.

The choice between solution polymerization and suspension polymerization depends on factors such as the desired properties of the EPDM products, production scale, and economic considerations.

In practice, various factors, including the desired EPDM characteristics, process efficiency, and environmental considerations, influence the selection of the polymerization method. Manufacturers often optimize their processes based on a combination of these factors to produce EPDM with the desired properties in an economically viable and environmentally sustainable manner.

In the current landscape, with a total installed capacity of 2’000 KTA distributed among 14 producers in about 33 active production lines, 87% of EPM/EPDM rubbers are produced using solution technology.

IPT introduces the 2nd generation of its EPM/EPDM solution technology, incorporating significant enhancements in the following aspects:

- Environmental emission and Carbon footprint

- Process control, safety, reliability and operation

- Product quality

- Capex, Equipment cost and Land utilization

- Utility consumption