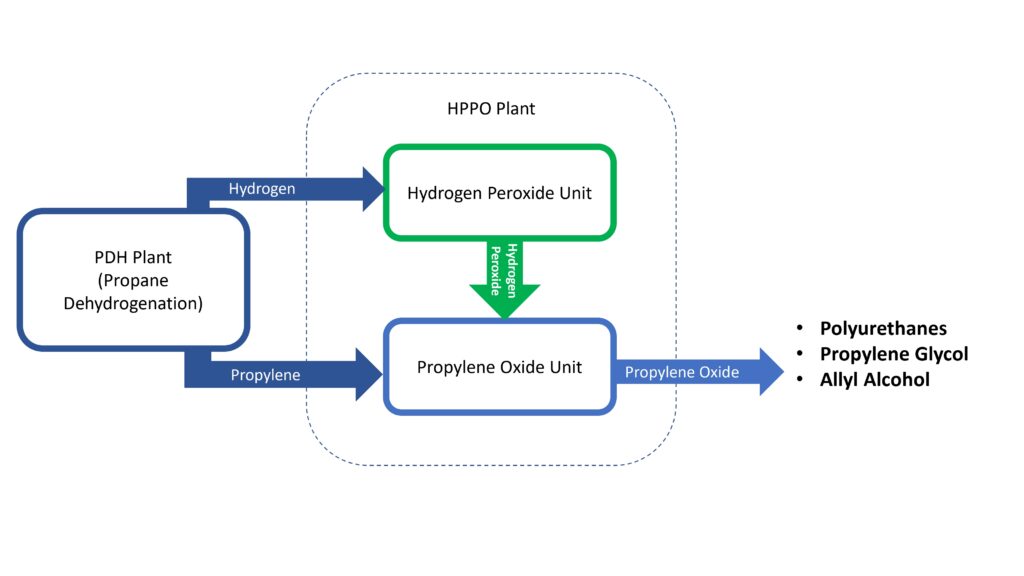

The propylene value chain in petrochemical industry, starting with propane, enables the production of diverse products. The latest technology for synthesis of Propylene oxide (PO), start from propylene using hydrogen peroxide (HPPO).

Propylene oxide finds extensive application in the manufacture of polyurethane foams, polyols, propylene glycols, polypropylene glycols, as well as various cosmetics and pharmaceutical products.

Integrating PDH (propane dehydrogenation) and HPPO (hydrogen peroxide propylene oxide) units in the same plant locations where Propylene and Hydrogen are produced, presents several advantages due to the relationship between the processes.

Such integration is highly innovative and efficient solution, that remarkably diminishes the overall CAPEX and OPEX of the entire plant, lowers the CO2 footprint and environmental impacts, serving to minimize plot area, equipment and storage requirements, optimize energy consumption, reduce operational, transportation and hazardous risks, and enables plant operator for better process integrity, control and reliability.

The surplus hydrogen generated from the PDH process can be judiciously employed as feedstock for hydrogen peroxide production, while the propylene can serve as the feedstock for the propylene oxide process.

Note: A typical 450 KTA PDH plant can produce, 56.25 T/hr of Propylene and 2.1 T/hr of Hydrogen (after H2 PSA).

Stay tuned for further updates!

#HPPO #PDH #innovation #IPTsrl #petrochemical #processtechnology #technologytransfer #processengineering #researchanddevelopment #R&D #Licensing